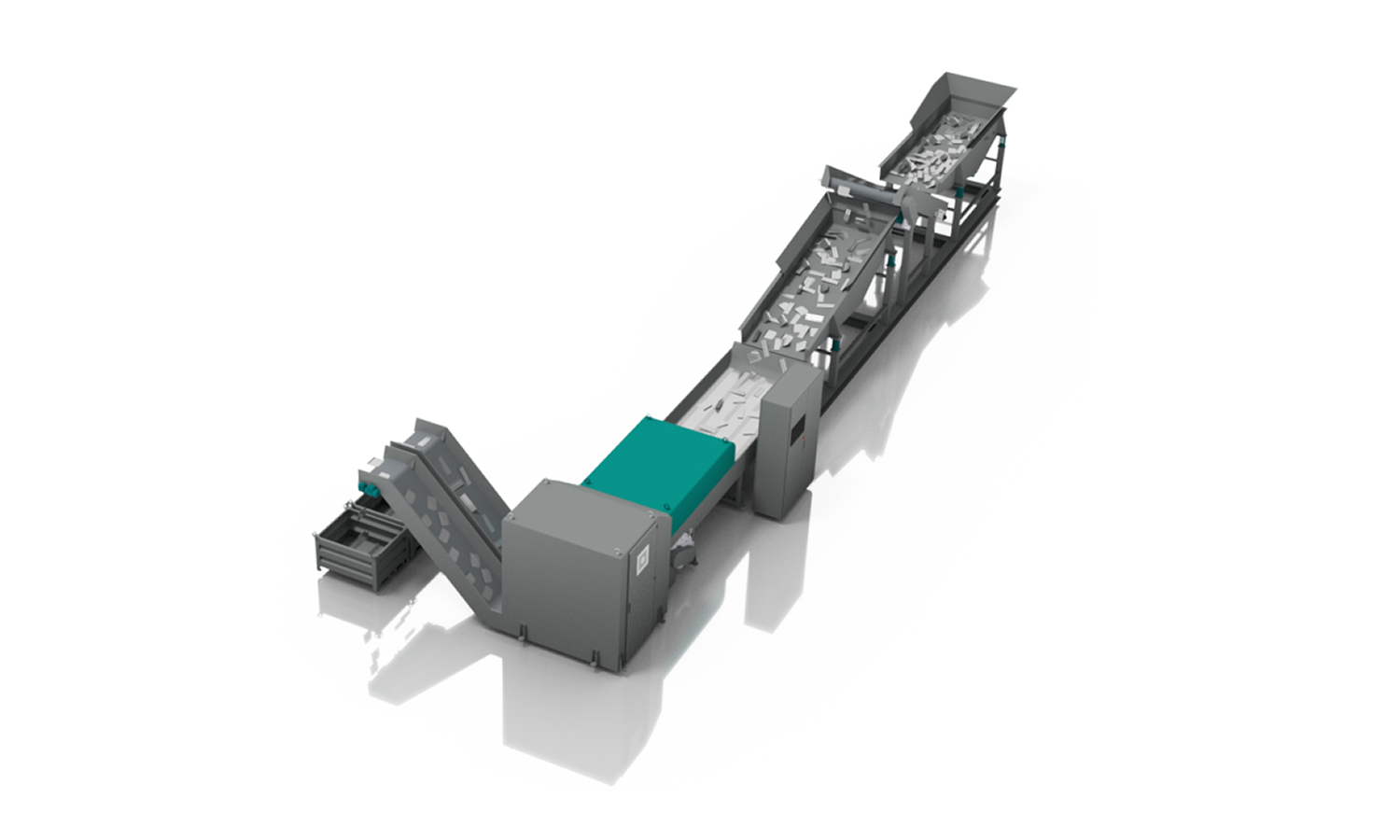

Die von cleansort angebotene schlüsselfertige Anlagentechnik beinhaltet anspruchsvolle und wartungsfreie Lasertechnik, die auf modernsten diodengepumpten Festkörperlasern aus dem Hause cleanLASER basiert. Die komplette Technologie zur Materialförderung und -vereinzelung gehört ebenso dazu wie die Sortierung mittels leistungsstarker paralleler Luftimpulstechnik.

The metallic old and new scrap can be fed from a bunker in almost any size class (from approx. 25 mm to 800 mm edge length). The conveying and separating technology then ensures transfer to the conveyor belt. Here the parts with a width of up to two meters are distributed evenly and as far as possible without overlap and accelerated to a transport speed of up to three meters per second.

Im weiteren Verlauf vermessen schnelle Laserscanner die vereinzelten Schrottstücke hinsichtlich ihrer Flächen-Geometrie. Diese Messung ist wichtig, um den Flächenschwerpunkt für die spätere Sortierung des jeweiligen Teils zu bestimmen.

Direkt im Anschluss an die schnelle Objekterkennung folgt die Laserbearbeitung mit dem cleansort-Modul. Die Reinigung und Messung des exakten Fingerabdrucks erfolgt innerhalb von nur sechs Millisekunden. Die Erfolgsrate der Messung beträgt trotz dieser sehr kurzen Dauer über 93 %. Somit können innerhalb eines Wimpernschlags fast 30 LIBS-Messungen mit dem System durchgeführt werden. Dabei legen die Bauteile bei jeder Entschichtung und Messung nur eine Strecke von etwa 20 mm zurück. Die enorm kurzen Bearbeitungszeiten ermöglichen somit die parallele Bearbeitung mehrerer nebeneinander liegender Teile oder auch den Abtrag von dickeren Lackschichten oder anderen relevanten Beschichtungen für die Messung.

Within the approximately seven-year development period of the technology, the system was thus brought to economic market maturity.

THE ADVANTAGES OF THE CLEANSORT SORTING TECHNOLOGY

HIGH PERFORMANCE PRE-ABLATION

The high performance pre-ablation allows reliable analysis of heavily contaminated or coated materials. Whether galvanized steels, scrap from waste incineration plants covered with a thick layer of soot and ash, or heavily rusted steels, all these materials can be reliably sorted thanks to high-performance pre-ablation.

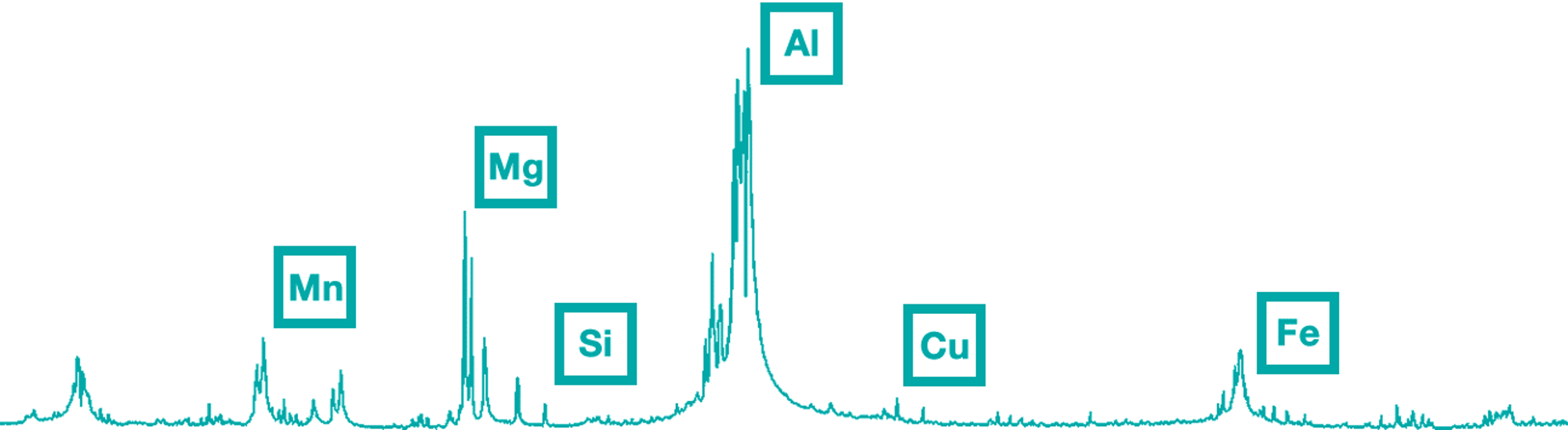

MULTIVARIABLE MATERIAL ANALYSIS

Für Schrottverwerter ist der flexible Einsatz der Anlagentechnik von besonderem Interesse. Aufgrund des breiten Messspektrums lässt sich die Anlage, nach einer Freigabe und Kalibrierung, auf Knopfdruck von der Sortierung von Buntmetallen auf bspw. die Sortierung von Stahl umschalten und sowohl eine qualitative als auch eine quantitative Analyse ausführen.

VARIABLE SEPARATION

The system can be freely configured: Starting with a conveyor belt width of 250 mm and only one measuring system up to a conveyor belt width of 2,000 mm and eight measuring systems, the plant can be adapted to the specific scrap.

HIGH THROUGHPUT THANKS TO SCANNING MEASURING SYSTEM

Thanks to the two-fraction sorting and the cascadable design of the system, high throughput rates can be achieved.