THE CLEAN2SORT MODULE

The process, developed in close cooperation with Clean-Lasersysteme GmbH (cleanLASER) and brought to market maturity at cleansort GmbH, is able to analyze the quantitative alloy content of a scrap piece within a few milliseconds.

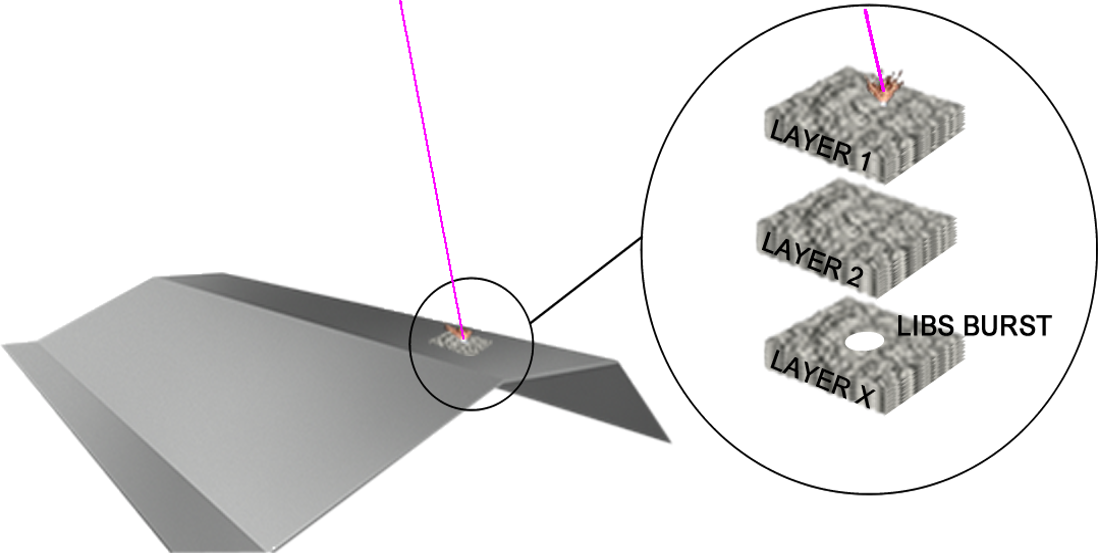

First, a high-power laser cleans a small area on the surface of a scrap piece. In the second sub-process, the same laser is used to perform laser-induced plasma spectroscopy (LIBS) on the previously cleaned and decoated area. The complete process is carried out in a continuous flow by means of a conveyor belt. Thanks to the 3D scanner technology installed in the clean2sort module, it is not only possible to follow the component with the laser beam, but also to process adjacent components with different heights.

The close development partnership of cleansort with Clean-Lasersysteme GmbH (cleanLASER), the market leader for sustainable laser beam cleaning technology, has created a solid technology base. cleanLASER's many years of experience in the field of laser technology also enable cleansort to make use of current laser technology.

In 2010, the managing directors of Clean-Lasersysteme GmbH were awarded the German Environmental Prize of the Deutsche Bundesstiftung Umwelt for the fundamental development and implementation of laser beam cleaning.

THE HOUSING

- Modular design

- Plug & Play

- Temperature controlled for use under harsh conditions

- Internal performance measurement and system monitoring

THE OBJECT RECOGNITION

The Object detection was adapted to the required throughputs and the associated high acquisition and analysis rates.

THE OPTICS

Since the high precision of the clean2sort module also requires exact positioning, 2D optics are used for beam deflection in X and Y direction. In addition to the scanning of any geometry, this also allows compensation of the feed motion when processing parts that are conveyed at 3 m/sec under the measuring system.

DIE SPEKTRALNALYSE

To ensure the required measurement accuracy of spectral analysis, a constant temperature of the spectrometer is indispensable and elementary important. Therefore, in addition to the general temperature control of the housing, a separate highly efficient temperature control of the spectrometer was developed. A housing milled from the solid with its own cooling circuit thus ensures constant analysis quality even under robust conditions.